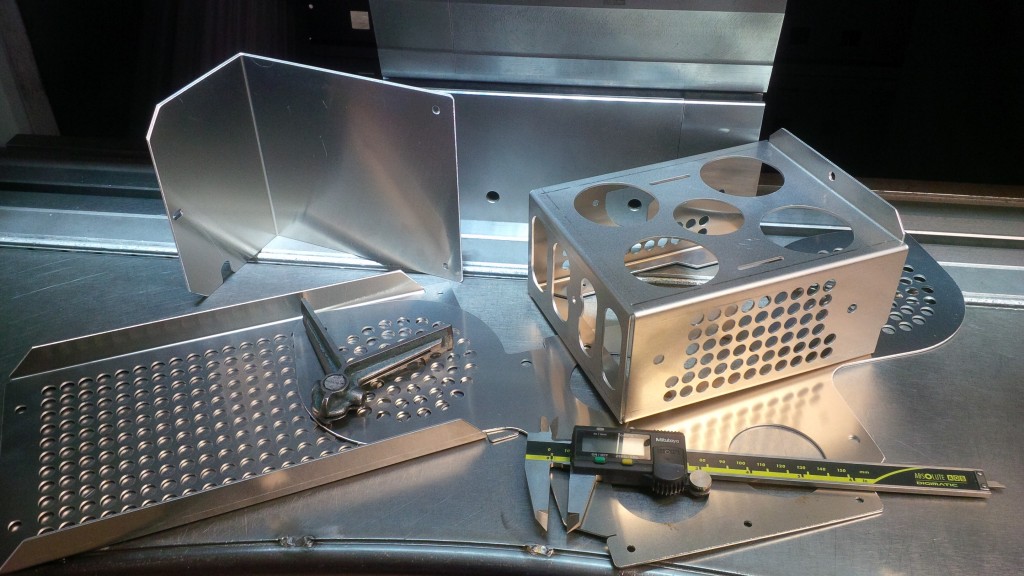

Magnetic sheet metal brake can bend items impossible for traditional box and pan brakes such as totally enclosed boxes triangles alternate bends on varyin.

Bending 2mm aluminium sheet.

Sheet aluminium can be cut without the need for a guillotine or tin snips which tend to deform the metal.

It is most economical to use a single bend radius throughout the design but if necessary you can utilize multiple radii.

Also known as press braking flanging die bending folding and edging this method is used to deform a material to an angular shape.

Bend radii minimum bend sizes.

In other words if you re bending 1 8 sheet use a tool with a 1 8 radius to form the inside of the bend.

This weakens the aluminium and creates a fracture line.

The bending of sheet metal with a punch and an array mounted at a folder is quite natural and normal.

Learn how to bend sheet metal so you.

Protocase tech tip video.

Quick video about bend radius watch more tech tip videos bend radii minimum bend sizes.

If you re bending 0 020 thick material use a 0 020 radius.

With a 2mm line you could be out of square by 2mm or the hole you just drilled is off 2mm.

Place the fracture line over the edge of a table and bend the overhang slightly downwards.

This is done through the application of force on a workpiece.

Medium strength alloy work hardens rapidly.

Bending sheet metal by hand is a manageable task if the piece of sheet metal is small and thin enough to handle.

The finer the marks the more accurate your bends and cuts will be.

For most applications with stainless steel or aluminum you can get away with a zero radius bend on anything under 0 050 thick.

Bending is one of the most common sheet metal fabrication operations.

Calculate the force required to fold 800 mm from sheets of 3 mm aluminium 25 kg mm2.

The force must exceed the material s yield strength to achieve a plastic deformation.

With the aid of a straight edge and a sharp knife score both sides of the aluminium sheet.