If the chosen sheet metal cannot be formed into the desired shape under the selected processing conditions the applied stresses are higher than the tensile strength of the sheet metal which causes cracks to form in the part.

Bending stiffness of sheet metal.

This test indicates that a vault structured sheet is three to five times stiffer than nonstructured sheet.

The inside bend radius should be equal to the thickness of the material that you re forming.

How large of a bend you put in the metal depends on the application and fitment of the piece.

To evaluate this property a three point bending test can be used.

In other words if you re bending 1 8 sheet use a tool with a 1 8 radius to form the inside of the bend.

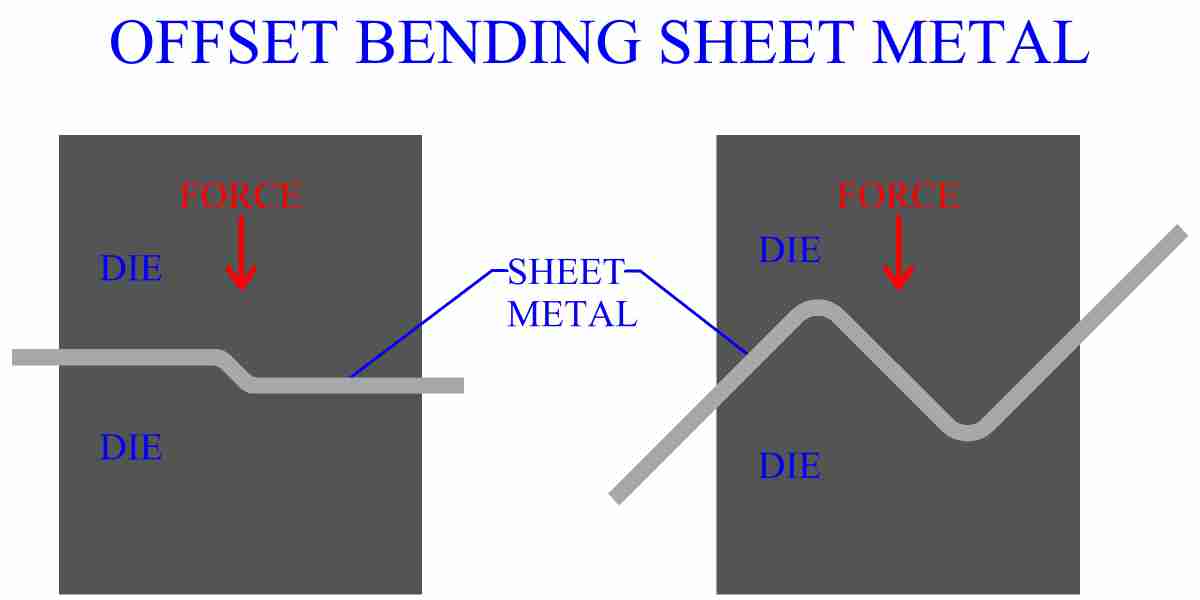

Similar to other metal forming processes bending changes the shape of the work piece while the volume of material will remain the same.

As a result a deflection versus bending force curve is obtained as shown infigure 5.

Bend relief and collars near pierced areas strengthen sheet metal parts.

The calculator counts the the total flat length according to the k factor you specify.

Folding over the edge of a piece of sheet metal will give the metal instant structural integrity.

If you re bending 0 020 thick material use a 0 020 radius.

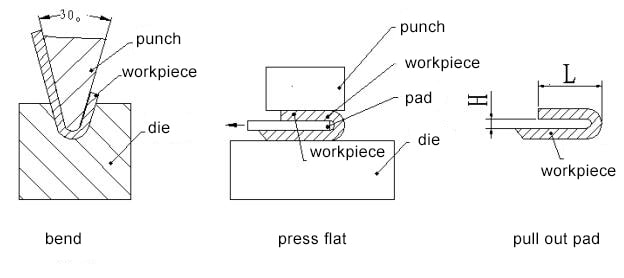

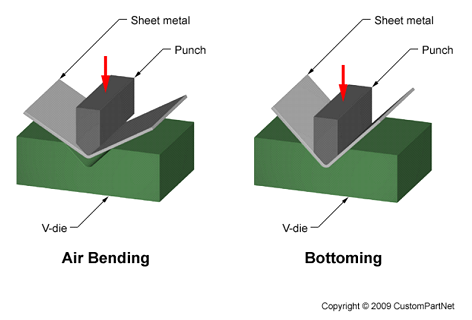

Sheet metal bending is the plastic deformation of the work over an axis creating a change in the part s geometry.

The program helps to easily calculate the real value of k factor for your material tool tooling.

The force must exceed the material s yield strength to achieve a plastic deformation.

These methods will give sheet metal the rigidity you need to use it in a structural or semi structural application.

The original shape is the flat sheet metal and formed components need to retain their shape permanently.

If you do not know the value of k factor then the program determining the the total flat length depending on the method of bending and stiffness of the material offers approximate values of the k factor.

All materials have some degree of elasticity including metal which is highly known for its stiffness.

Also known as press braking flanging die bending folding and edging this method is used to deform a material to an angular shape.

Structured sheet metal has increased bending stiffness.

In this article we will discuss sheet metal design guidelines for manufacturing parts using sheet metal press bending.

Bending is one of the most common sheet metal fabrication operations.

Grain structure in the metal sheet is critical for avoiding cracks in sheet metal parts with lugs or tabs that are cut on.

Sheet metal edge bending.

Following all sheet metal design guidelines is very difficult in the complex part.

This happens for two reasons.

To protect the part to increase stiffness and for cosmetic appearance.

Following a plastic deformation that we make to bend the metal an elastic recovery followed once we remove the load causing the metal to attempt moving back in place.

Therefore exceptions can be there for complex features design.

Why does sheet metal spring back.